Contact Info

- Russia, Moscow, Mytishy, Olimpic pr. 29/2

- +7 495 924 0991

- info@itl-engg.com

Warning: count(): Parameter must be an array or an object that implements Countable in /var/www/u0988235/data/www/itl-engg.com/components/com_k2/models/item.php on line 853

TO INVESTORS, CUSTOMERS, GENERAL CONTRACTORS, ARCHITECTS

- Requirements compilation and coordination of target groups interests

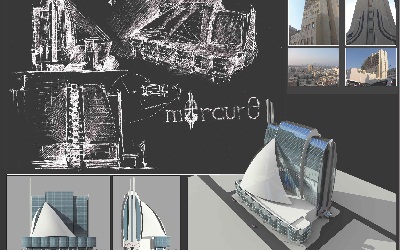

- Concept design and preliminary calculations

- Iteration assessment of the project budget

- Elaboration of technical specifications and tender packages

- Organizing of performance testing

- Organizing tenders, giving recommendations on the winner nomination

- Analysis and optimization of the energy efficiency

- Preparation of requirements on BMU and media-façades use

- Development and approval of the Technical Requirements

OUR Approach

We do not limit our role on a project to pure understanding of local codes and regulations but we do aim at interpreting the principles and concerns forming the core of such codes and regulations. ITL Engineering key contribution for the project is a clear understanding of facade technology from basic principles to complex applications which results in coherent advice to our clients.

Due to thorough specialist knowledge and application of the modern design tools we reconcile design requirements, technical feasibility and financial possibilities.

Pre-Tender Stage

As part of design team ITL Engineering helps to figure out the principle parameters characteristic for a particular facade, and building up the basis of the project specification.

We generate a detailed specification of the project reflecting the design intent, defining performance requirements, aesthetics and methods of construction dependent from site conditions and project budget. At this stage we can elaborate detailed design solutions fully corresponding to the Specification and founded on value engineering principles. The detailed design can then be formally issued to the selected sub-contractor for preparation of the project shop drawings.

To ensure clear understanding of design specification by every potential sub-contractor ITL Engineering specialists attend at pre-tender meetings, where they discuss the technical content of the project and highlight problematic areas.

Tender Stage

ITL Engineering specialists comment on the suitability of companies applying for a tender, assessing the bids and compiling reports on the bidders qualifications.

We prepare a technical evaluation for each tender proposal, highlighting strengths and weaknesses. In order to give a complete assessment of potential sub-contractors ability to complete the bespoke work package effectually, ITL Engineering team members can visit sub-contractors factory and office.

Design Stage

ITL Engineering team compiles the project design analysis. Using the latest structural analysis software and product knowledge our structural engineers solve a whole range of challenging engineering problems to obtain the optimum design solutions.

We perform complete technical audits of designs proposed by the sub-contractors to ensure the conformity to the project specification and suitability of design, making sure it meets the technical, performance and aesthetic project requirements.

Fabrication Stage

Starting from the actual faсade manufacturing we attend the factory and inspect quality procedures, and check on the progress of fabrication. Each factory visit is supported with a written report.

We do also attend prototype testing and if it is necessary, we offer advice and propose various solutions for problems elimination or for further system improvements to the advantage of the project.

Installation Stage

For the site installation we can arrange a specialized faсade supervisor - an engineer experienced in controlling the works and making sure these are carried out with a proper level of expertise, workmanship and quality, and in full compliance with the shop drawings and specification. The engineer can as well report on the installation progress.

Otherwise, monthly site visits by a faсade consultancy engineer can be arranged to provide expert advice and proper resolution of on-site issues.

We attend on-site performance testing to make sure the test procedure given in the Specification is observed and the faсade elements perform accordingly.

Project Completion Stage

At the end of the project ITL Engineering specialists perform a full inspection of the installed building envelope, review the sub-contractors as-built drawings and maintenance manuals and prepare a final defects report.